Quality control

Quality control is a critical aspect of ensuring that production in garments and shoes meet the required standards. Attention to detail is essential throughout the production process to guarantee that the final products are of high quality and meet customer expectations.

Here Are Some Key Points For Effective Quality Control :

We establish clear quality standards and specifications for your products. These standards should cover aspects such as materials, workmanship, sizing, stitching, color consistency, and overall appearance. Designer should send up an approved Spec sheet to work with.

We implement quality control processes at every stage of production, from raw material inspection to final product checks. This includes regular inspections, testing (if required and there may be an additional charge for this), and weekly audits to identify and rectify any issues early on once production is started.

We implement quality control processes at every stage of production, from raw material inspection to final product checks. This includes regular inspections, testing (if required and there may be an additional charge for this), and weekly audits to identify and rectify any issues early on once production is started.

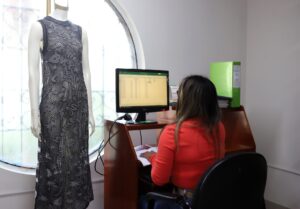

We ensure that our staff are well-trained in quality control procedures and have the necessary skills to identify defects and inconsistencies. Regular training sessions can help improve attention to detail and overall quality awareness and they are regularly trained and sent on courses to ensure they meet these standards.

We ensure that our staff are well-trained in quality control procedures and have the necessary skills to identify defects and inconsistencies. Regular training sessions can help improve attention to detail and overall quality awareness and they are regularly trained and sent on courses to ensure they meet these standards.

We conduct thorough inspections and tests of materials and components (upon request, as this may incur an additional testing charge) on finished products to ensure they meet the required specifications.

We conduct thorough inspections and tests of materials and components (upon request, as this may incur an additional testing charge) on finished products to ensure they meet the required specifications.

We maintain detailed records of quality control checks, test results, and any corrective actions taken. This documentation can help you track quality trends, identify recurring issues, and implement preventive measures. We also ensure all shipment documentation is done accordingly so you can access all the Free-Trade benefits when shipping.

We maintain detailed records of quality control checks, test results, and any corrective actions taken. This documentation can help you track quality trends, identify recurring issues, and implement preventive measures. We also ensure all shipment documentation is done accordingly so you can access all the Free-Trade benefits when shipping.

We work closely with your suppliers to ensure they adhere to high standards and provide high-quality materials and components. Regular communication and feedback can help maintain quality consistency throughout the supply chain.

We monitor production timelines closely to ensure that products are shipped on time. Delays in production can impact quality control processes and lead to rushed production, which may result in compromised quality.

We encourage feedback from customers, employees, and other stakeholders to identify areas for improvement. Use this feedback to continuously enhance your quality control processes and improve overall product quality.

We encourage feedback from customers, employees, and other stakeholders to identify areas for improvement. Use this feedback to continuously enhance your quality control processes and improve overall product quality.

We implement robust quality control processes and foster a culture of continuous improvement, you can ensure that your garment, shoe or accessory production will be shipped on time at the expected quality level.